Applications

QA of Small Lenses

Mobile / cell phone and automotive sensor lenses and lens assemblies pose unique challenges for centering and alignment quality assurance.

Using LAS, the quality of miniature lens assemblies can be quickly determined. To do this, lens assemblies are placed on the LAS rotary air bearing chuck, shown here on the left, which has been de-tilted and centered to < 0.2 μm TIR as measured by calibrated indicator probe

Lens decenters can then be measured by LAS relative to the optical axis of the top lens of the assembly. Proof of concept has been performed by taking ten “good” and ten “bad” assemblies, as measured by MTF. Strong correlation was seen between two LAS measurements:

-

Average lens de-center relative to top lens of the assembly

-

Assembly tilt trend of de-centers through the lens stack

Those two measurements could then be applied to an LAS-based pass / fail criteria. Used in a production environment, this QA technique saves time relative to traditional measurement of MTF for each assembly.

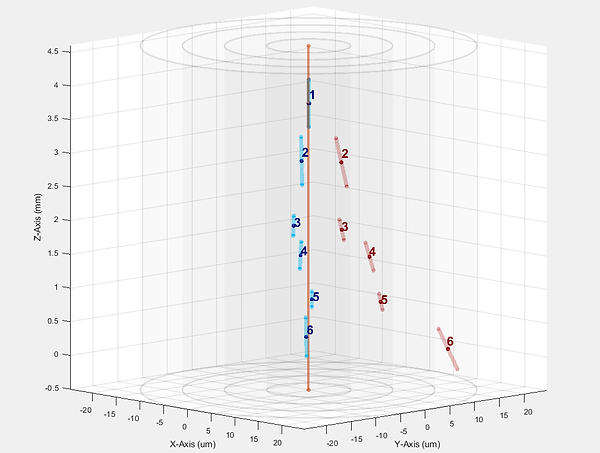

Use of CalcuLens™ 3D Viewer software helps LAS users to visualize the differences between a Passed (blue) and a Failed (red) assembly. Vectors have length equal to lens center thickness (CT) and depict lens decenter (dot) and tilt (vector direction) in 3-D space. Quality of lens assemblies can be easily categorized based on this criteria, even to the extent of identifying best-of-the-best or marginal assemblies.

Read more about Multi-Lens Inspection and CalcuLens™ 3D Viewer HERE